Joanna Cosgrove, Contributing Editor10.25.23

The easier a package is for consumers to recycle, the more likely they are to recycle it. Mono-material packaging makes recycling easier, but some applications are more complex than others to translate into a mono-material format, including multi-component configurations like lipsticks, compacts and airless packages. Packaging providers, however, are overcoming challenges with robust new enthusiasm, enabling brands to use their packaging as a tangible representation of their commitment to the environment and their consumers.

One of mono-material packaging’s chief benefits is that it doesn’t need to be disassembled prior to disposal. “There are still a lot of consumers that do not realize materials need to be separated in order to be recycled,” says Sarah Sommer, vice president of business development, Alder Packaging, noting the potential for this packaging to bridge a major disconnect among well-intentioned consumers.

In addition to helping increase recycling rates, Jing Santos, co-founder, Accipiter Beauty Packaging LLC, says mono-material packaging also delivers a potential for back-end cost savings. “Mono-material solutions optimize the value of a recycled package and allow for curbside recycling [and] brands can avoid the costs associated with post-consumer collection and disassembly,” he says.

Demand for this form of packaging is on the climb. “Over the past year, the demand for mono-material packaging within the beauty and personal care segment has experienced a remarkable upswing,” comments Rick Ponte, vice president of project engineering, APC Packaging. “This trend reflects the growing consciousness among both brands and consumers regarding the environmental impact of packaging. As a result, there has been a notable surge in requests for packaging solutions that are not only visually appealing, but also recyclable, reusable and environmentally responsible.”

“Consumers feel the weight of the plastic waste crisis and are looking to brands to help them live a more sustainable lifestyle,” says Eastman’s Tara Cary, segment market manager for cosmetics packaging. “In fact, over 70% of consumers surveyed feel that brands need to do more to support them in living a sustainable lifestyle.” One of the often-mentioned frustrations with recycling from consumers is that it is too complicated.

“In addition,” Cary says, “regulations are continuing to push the adoption of recyclable packages. For brands this means that they need to make the entire package recyclable, not just one or two components. For example, PPWR is requiring that all packaging placed on the market in EU member states be fully recyclable (designed for recycling) by 2030 and recycled at scale by 2035. Similarly in California, all new packaging must be recyclable or compostable by 2032.”

This combination of consumer push and regulatory pull, she says, has created more requests for materials suitable for RIC1 stream mono-material packages that can incorporate high levels of recycled content without creating compromises in aesthetics or performance.

Eastman, in partnership with International Cosmetic Suppliers (ICS), has designed a sustainably sourced, recyclable and refillable compact using Cristal One Renew-100, a PET made with up to 100% certified recycled content that’s manufactured via molecular recycling and compatible with the RIC1 stream.

“Molecular recycling produces virgin-grade starting materials so there is no trade-off in performance or aesthetics,” Cary explains, noting that the technology also delivers an improved GHG footprint (20% to 30% lower) when compared to processes using fossil feedstocks and enables infinite ability to recycle polymers for a truly circular economy. “By using mono-material PET, we achieve an overall reduction in environmental impact, scrap material, transportation and emissions while serving in a refillable and recyclable application that has a longer product life cycle and a positive end-of-life story.”

“Finding a suitable mono-material that harmoniously meets functional requirements like barrier properties, durability, and aesthetics can be intricate,” says APC’s Ponte, adding that APC’s PP and PET mono-material packaging have played a central role in recent brand partnerships and have extended into a diverse and evolving array of jars, tubes and components. “The design and aesthetic versatility might be comparatively limited compared to multi-material alternatives, posing considerations for brands with distinctive packaging preferences. Certain products might necessitate specific packaging features that are more feasible to achieve using multi-material approaches.”

There’s also the issue of integrating mono-material use and package production into current cost structures. “In general, mono-material packaging is about the same cost as traditional packaging; [however] I think we’re still paying for the R&D and innovation to launch mono,” says Brian Saputo, CTO and president of Seacliff Beauty. “Additionally, mono is competing with a commoditized industry that has built systems and processes to cost save current manufacturing. I think that eventually, mono-material packaging could be less expensive.”

Another challenge he points to is engineering new packs and molding resins in a way that mimics the currently used materials. “For example, creating and molding a PE part that functions like a metal spring or elastomer material,” he says. “The good news is that we continue to see strong progress and IP in this area; more and more designs become available regularly.”

Seacliff Beauty offers PE and Green PE Sugar Cane mono-material airless packaging, as well as mono-materials packaging that can be PP, PET, PET, Sugarcane or made with #tide Ocean-Bound Plastic materials (PET, PP, HDPE and LDPE).

Seacliff recently produced the Peace Out Vitamin C Glow Stick in a mono-material PET applicator stick made with 50% PCR PET (fill capacity: 3g/0.10 oz). Seacliff’s Vonda Simon, founder and CEO, said the package seamlessly matched the brand’s aesthetic of simplicity, opting for a vibrant orange color with silk screen printing decoration.

“Peace Out has used this same packaging style for multiple SKUs in their line,” says Simon. “It is a great option as it is a sleek and simple design that offers sustainable solutions such as mono-material, PCR, and can also be used as a refillable package (however, not in this specific case).”

FusionPKG’s Prestige Collection is the company’s latest example of recycle-ready packaging with certified mono-material options and 100% PCR possibilities, and it integrates with the company’s Airless-One and Atmos-One pump engine technology. The collection showcases a range of double wall airless polypropylene packaging available in a variety of sizes and actuator style options with deco capabilities that include a variety of inner/outer frosted, glossy, matte and gradient sprays, injected color, hot stamp and silk screen decoration applications.

Alder Packaging has also been busy working on mono-material solutions across a wide range of materials and formats, including mono-material airless packages that are fully recyclable in PP, a variety of stick and lipstick items for skincare and color cosmetics in PET and PP, and mono-material lipsticks that are also refillable (PET, PP).

“Alder Packaging was founded to bring sustainable packaging to the forefront of all development projects we have the privilege to work on,” explains Sommer, adding that the company typically helps its customers see the beauty of sustainability before pivoting to a mixed material option if the project requires.

The company’s most exciting mono-material development is its 100% aluminum lipstick package (including the mechanisms) and it’s fully qualified for mass production by Axilone. Sommer says several sizes and styles are available as stock, and the outer case can be fully customized to suit brand needs.

Pibiplast SpA offers mono-material mascara packaging, as well as mascara components, and 5-15ml bottles suitable for lip glosses, concealers, eye shadows and foundations.

“The real challenge was to mold caps, but above all, rods in such a particular material as PET,” comments Mary Beretta, head of product marketing management. “The experience we have gained has enabled us to develop larger caps and rods [larger than those of a mascara], thus being able to offer mono-material packaging also for different product types (i.e., lip gloss and all-over products), where the dimensions are larger and therefore the challenge was greater.”

Pibiplast’s latest mono-material brand collaboration was with Idun Minerals, a Swedish cosmetic brand with a strong commitment to environmental responsibility. Mascara Vatn Volume 38°C from Idun Minerals has a cap, rod and bottle made in 100% R-PET.

“The packaging is recycled and easy to recycle after use [and] the 15ml container is paired with a bio-based fiber applicator derived from a renewable source,” Beretta says. The brand opted for black silk screening on the bottle and on top of the cap, keeping it simple, to minimize the impact of emissions, which can be a byproduct of more complex decorations.

“The brand focuses on creating beauty and skincare products that not only enhance individual well-being but also contribute to a healthier planet,” she explains. “Our mascara packaging is eco-friendly twice over, since it’s recycled and can be recycled again after use.”

Accipiter Beauty Packaging offers mono-material airless dispensing solutions in both 100% PP as well as 100% PE. The company also offers commercialized solutions for mono-material lotion pumps and treatment pumps, jar/closure solutions—and mono-material spray pumps are in development.

One of Accipiter’s newest mono-material solutions pairs an all-plastic mono-material PP lotion pump applied to a PET bottle. “This configuration allows for the complete package to be recycled without disassembly and meets the preferred guidelines of recycling programs,” says the company’s Santos. “In this case, the PP and the PET materials can be easily mechanically sorted.”

Ourself by GLO Pharma found the concept intriguing and for its Daily Purifying Cleanser, sought a fully recyclable lotion pump and bottle package with PCR content. Accipter’s patented mono-material PP lotion pump paired with a 200ml PET bottle was the perfect fit. The pump was molded in a neutral eggshell color and the bottle in clear with a matte spray and one-color silkscreen, resulting in a presentation that’s simple, clean, elegant and fully recyclable.

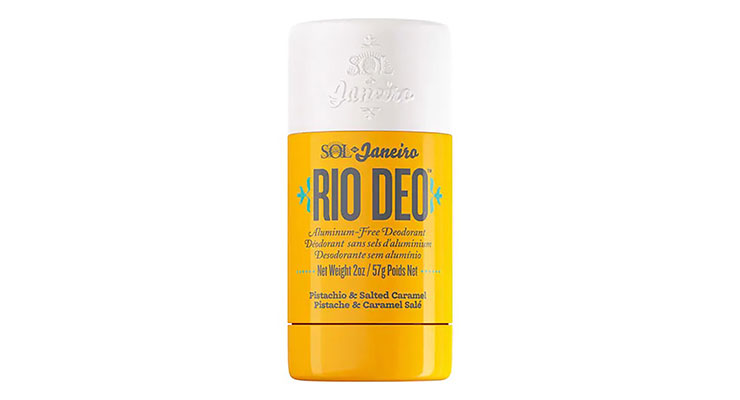

Viva Healthcare Packaging (Canada) Ltd. has been making unique, mono-material polypropylene tubes and tube accessories, including caps and in-mold label decoration, for over a decade. The company also offers more than 20 deodorant stick options, including oval and round shapes, top- and bottom-fills, solid and semi-solid configurations. This summer, Viva earned two AmeriStar 2023 awards: Best Sustainable Packaging for Axe Green Geranium Deodorant Stick and Top in Design Excellence for Sol de Janeiro Rio Deo Refillable Deodorant Stick.

The 2oz. Sol de Janeiro Rio Deo Refillable Deodorant Stick replaces direct printed, virgin, single-use packaging with components that are decorated using in-mold label technology. The package is made from recycled material, including a refill cartridge system. Its stick and bottom dial are custom-colored, and the brand invested in a matte cap embossed with their logo.

The 2.6oz Axe Green Geranium Deodorant Stick is comprised of an injection-molded cap, dial and inner screw and it’s virgin resin-free. “All pieces are molded with maximum recycled polypropylene content,” says Viva’s Melanie Gaudun, business development manager, and the “barrel and cap are decorated with polypropylene in-mold label technology in a continuous design from barrel to cap.”

“In sum, while the adoption of mono-material packaging brings forth undeniable benefits, careful evaluation of challenges and trade-offs is essential,” concludes APC Packaging’s Ponte. “Striking the right balance between environmental advantages and practical considerations remains pivotal for manufacturers looking to integrate this approach effectively.”

All Woodacity solutions are sourced from sustainably managed European forests, with optional PEFC or FSC certification, and each component has its own, unique grain pattern. Each product in the range is designed, produced, assembled and decorated at Quadpack Wood factory in Spain, which uses clean manufacturing using renewable energy, while temperature control and wood drying ovens are fueled by a biomass boiler using production scrap. The products are also customizable via a variety of decoration options.

One of mono-material packaging’s chief benefits is that it doesn’t need to be disassembled prior to disposal. “There are still a lot of consumers that do not realize materials need to be separated in order to be recycled,” says Sarah Sommer, vice president of business development, Alder Packaging, noting the potential for this packaging to bridge a major disconnect among well-intentioned consumers.

In addition to helping increase recycling rates, Jing Santos, co-founder, Accipiter Beauty Packaging LLC, says mono-material packaging also delivers a potential for back-end cost savings. “Mono-material solutions optimize the value of a recycled package and allow for curbside recycling [and] brands can avoid the costs associated with post-consumer collection and disassembly,” he says.

Demand for this form of packaging is on the climb. “Over the past year, the demand for mono-material packaging within the beauty and personal care segment has experienced a remarkable upswing,” comments Rick Ponte, vice president of project engineering, APC Packaging. “This trend reflects the growing consciousness among both brands and consumers regarding the environmental impact of packaging. As a result, there has been a notable surge in requests for packaging solutions that are not only visually appealing, but also recyclable, reusable and environmentally responsible.”

Gauging Consumer Preferences

A global skincare study spearheaded by the consumer insights team at Eastman and conducted by a third party revealed that consumers want cosmetic packaging that contains trustworthy claims they can verify; recyclable packages that don’t force them to make aesthetic or performance tradeoffs; recycled content in meaningful amounts; and clear messaging provided on recycled content details.“Consumers feel the weight of the plastic waste crisis and are looking to brands to help them live a more sustainable lifestyle,” says Eastman’s Tara Cary, segment market manager for cosmetics packaging. “In fact, over 70% of consumers surveyed feel that brands need to do more to support them in living a sustainable lifestyle.” One of the often-mentioned frustrations with recycling from consumers is that it is too complicated.

“In addition,” Cary says, “regulations are continuing to push the adoption of recyclable packages. For brands this means that they need to make the entire package recyclable, not just one or two components. For example, PPWR is requiring that all packaging placed on the market in EU member states be fully recyclable (designed for recycling) by 2030 and recycled at scale by 2035. Similarly in California, all new packaging must be recyclable or compostable by 2032.”

This combination of consumer push and regulatory pull, she says, has created more requests for materials suitable for RIC1 stream mono-material packages that can incorporate high levels of recycled content without creating compromises in aesthetics or performance.

Eastman, in partnership with International Cosmetic Suppliers (ICS), has designed a sustainably sourced, recyclable and refillable compact using Cristal One Renew-100, a PET made with up to 100% certified recycled content that’s manufactured via molecular recycling and compatible with the RIC1 stream.

“Molecular recycling produces virgin-grade starting materials so there is no trade-off in performance or aesthetics,” Cary explains, noting that the technology also delivers an improved GHG footprint (20% to 30% lower) when compared to processes using fossil feedstocks and enables infinite ability to recycle polymers for a truly circular economy. “By using mono-material PET, we achieve an overall reduction in environmental impact, scrap material, transportation and emissions while serving in a refillable and recyclable application that has a longer product life cycle and a positive end-of-life story.”

Navigating Challenges

Despite its eco-advantages, mono-material packaging does have a few noteworthy caveats.“Finding a suitable mono-material that harmoniously meets functional requirements like barrier properties, durability, and aesthetics can be intricate,” says APC’s Ponte, adding that APC’s PP and PET mono-material packaging have played a central role in recent brand partnerships and have extended into a diverse and evolving array of jars, tubes and components. “The design and aesthetic versatility might be comparatively limited compared to multi-material alternatives, posing considerations for brands with distinctive packaging preferences. Certain products might necessitate specific packaging features that are more feasible to achieve using multi-material approaches.”

There’s also the issue of integrating mono-material use and package production into current cost structures. “In general, mono-material packaging is about the same cost as traditional packaging; [however] I think we’re still paying for the R&D and innovation to launch mono,” says Brian Saputo, CTO and president of Seacliff Beauty. “Additionally, mono is competing with a commoditized industry that has built systems and processes to cost save current manufacturing. I think that eventually, mono-material packaging could be less expensive.”

Another challenge he points to is engineering new packs and molding resins in a way that mimics the currently used materials. “For example, creating and molding a PE part that functions like a metal spring or elastomer material,” he says. “The good news is that we continue to see strong progress and IP in this area; more and more designs become available regularly.”

Seacliff Beauty offers PE and Green PE Sugar Cane mono-material airless packaging, as well as mono-materials packaging that can be PP, PET, PET, Sugarcane or made with #tide Ocean-Bound Plastic materials (PET, PP, HDPE and LDPE).

Seacliff recently produced the Peace Out Vitamin C Glow Stick in a mono-material PET applicator stick made with 50% PCR PET (fill capacity: 3g/0.10 oz). Seacliff’s Vonda Simon, founder and CEO, said the package seamlessly matched the brand’s aesthetic of simplicity, opting for a vibrant orange color with silk screen printing decoration.

“Peace Out has used this same packaging style for multiple SKUs in their line,” says Simon. “It is a great option as it is a sleek and simple design that offers sustainable solutions such as mono-material, PCR, and can also be used as a refillable package (however, not in this specific case).”

New-To-Market Innovations

FusionPKG has also executed the engineering legwork to evolve its mono-material offerings. According to the company’s Brady Bacchus, marketing manager, FusionPKG’s Airless-One and Atmos-One Mono-Material Pump Engine Technology leverage the benefits of PP to provide mono-material, recycling-ready, airless and atmospheric packaging without sacrificing aesthetics or performance. The company is also on track to expand those offerings to provide a larger assortment of designs with 175+ mono-material pump engine package options by 2024.FusionPKG’s Prestige Collection is the company’s latest example of recycle-ready packaging with certified mono-material options and 100% PCR possibilities, and it integrates with the company’s Airless-One and Atmos-One pump engine technology. The collection showcases a range of double wall airless polypropylene packaging available in a variety of sizes and actuator style options with deco capabilities that include a variety of inner/outer frosted, glossy, matte and gradient sprays, injected color, hot stamp and silk screen decoration applications.

Alder Packaging has also been busy working on mono-material solutions across a wide range of materials and formats, including mono-material airless packages that are fully recyclable in PP, a variety of stick and lipstick items for skincare and color cosmetics in PET and PP, and mono-material lipsticks that are also refillable (PET, PP).

“Alder Packaging was founded to bring sustainable packaging to the forefront of all development projects we have the privilege to work on,” explains Sommer, adding that the company typically helps its customers see the beauty of sustainability before pivoting to a mixed material option if the project requires.

The company’s most exciting mono-material development is its 100% aluminum lipstick package (including the mechanisms) and it’s fully qualified for mass production by Axilone. Sommer says several sizes and styles are available as stock, and the outer case can be fully customized to suit brand needs.

Pibiplast SpA offers mono-material mascara packaging, as well as mascara components, and 5-15ml bottles suitable for lip glosses, concealers, eye shadows and foundations.

“The real challenge was to mold caps, but above all, rods in such a particular material as PET,” comments Mary Beretta, head of product marketing management. “The experience we have gained has enabled us to develop larger caps and rods [larger than those of a mascara], thus being able to offer mono-material packaging also for different product types (i.e., lip gloss and all-over products), where the dimensions are larger and therefore the challenge was greater.”

Pibiplast’s latest mono-material brand collaboration was with Idun Minerals, a Swedish cosmetic brand with a strong commitment to environmental responsibility. Mascara Vatn Volume 38°C from Idun Minerals has a cap, rod and bottle made in 100% R-PET.

“The packaging is recycled and easy to recycle after use [and] the 15ml container is paired with a bio-based fiber applicator derived from a renewable source,” Beretta says. The brand opted for black silk screening on the bottle and on top of the cap, keeping it simple, to minimize the impact of emissions, which can be a byproduct of more complex decorations.

“The brand focuses on creating beauty and skincare products that not only enhance individual well-being but also contribute to a healthier planet,” she explains. “Our mascara packaging is eco-friendly twice over, since it’s recycled and can be recycled again after use.”

Accipiter Beauty Packaging offers mono-material airless dispensing solutions in both 100% PP as well as 100% PE. The company also offers commercialized solutions for mono-material lotion pumps and treatment pumps, jar/closure solutions—and mono-material spray pumps are in development.

One of Accipiter’s newest mono-material solutions pairs an all-plastic mono-material PP lotion pump applied to a PET bottle. “This configuration allows for the complete package to be recycled without disassembly and meets the preferred guidelines of recycling programs,” says the company’s Santos. “In this case, the PP and the PET materials can be easily mechanically sorted.”

Ourself by GLO Pharma found the concept intriguing and for its Daily Purifying Cleanser, sought a fully recyclable lotion pump and bottle package with PCR content. Accipter’s patented mono-material PP lotion pump paired with a 200ml PET bottle was the perfect fit. The pump was molded in a neutral eggshell color and the bottle in clear with a matte spray and one-color silkscreen, resulting in a presentation that’s simple, clean, elegant and fully recyclable.

Viva Healthcare Packaging (Canada) Ltd. has been making unique, mono-material polypropylene tubes and tube accessories, including caps and in-mold label decoration, for over a decade. The company also offers more than 20 deodorant stick options, including oval and round shapes, top- and bottom-fills, solid and semi-solid configurations. This summer, Viva earned two AmeriStar 2023 awards: Best Sustainable Packaging for Axe Green Geranium Deodorant Stick and Top in Design Excellence for Sol de Janeiro Rio Deo Refillable Deodorant Stick.

The 2oz. Sol de Janeiro Rio Deo Refillable Deodorant Stick replaces direct printed, virgin, single-use packaging with components that are decorated using in-mold label technology. The package is made from recycled material, including a refill cartridge system. Its stick and bottom dial are custom-colored, and the brand invested in a matte cap embossed with their logo.

The 2.6oz Axe Green Geranium Deodorant Stick is comprised of an injection-molded cap, dial and inner screw and it’s virgin resin-free. “All pieces are molded with maximum recycled polypropylene content,” says Viva’s Melanie Gaudun, business development manager, and the “barrel and cap are decorated with polypropylene in-mold label technology in a continuous design from barrel to cap.”

The Future Looks Bright

Seacliff’s Saputo, is excited about the impact mono-material offerings are poised to have in the near future. “We rarely hear from brands that have no interest in sustainability [and] sustainable packaging continues to be one of the strongest influences on brands in the personal care segment,” he says. “Directionally, it’s the right choice [and it’s] been a powerful campaign driving strong interest.”“In sum, while the adoption of mono-material packaging brings forth undeniable benefits, careful evaluation of challenges and trade-offs is essential,” concludes APC Packaging’s Ponte. “Striking the right balance between environmental advantages and practical considerations remains pivotal for manufacturers looking to integrate this approach effectively.”

Quadpack Debuts Woodacity, a Bespoke, Mono-Material Range in Wood

Quadpack’s Woodacity line was recently expanded to include award-winning closures that function without inners and refillable pack systems for easy dismantling, as well as a full collection that spans lipsticks, compacts, jars and closures for perfume bottles, lotion packs and tubes.All Woodacity solutions are sourced from sustainably managed European forests, with optional PEFC or FSC certification, and each component has its own, unique grain pattern. Each product in the range is designed, produced, assembled and decorated at Quadpack Wood factory in Spain, which uses clean manufacturing using renewable energy, while temperature control and wood drying ovens are fueled by a biomass boiler using production scrap. The products are also customizable via a variety of decoration options.